Sealers are instruments for sealing well plates with special films or plates. Compared to cappers, these sealers are not reusable but seal the well plates better. Therefore, sealing via sealers or heat sealers is often better, making the method particularly suitable for storage-based applications and PCR, qPCR and other assays.

Ultraseal LITE is a semi-automated heat sealer and is suitable for low to medium throughput laboratories. This sealing process utilises individual plates.

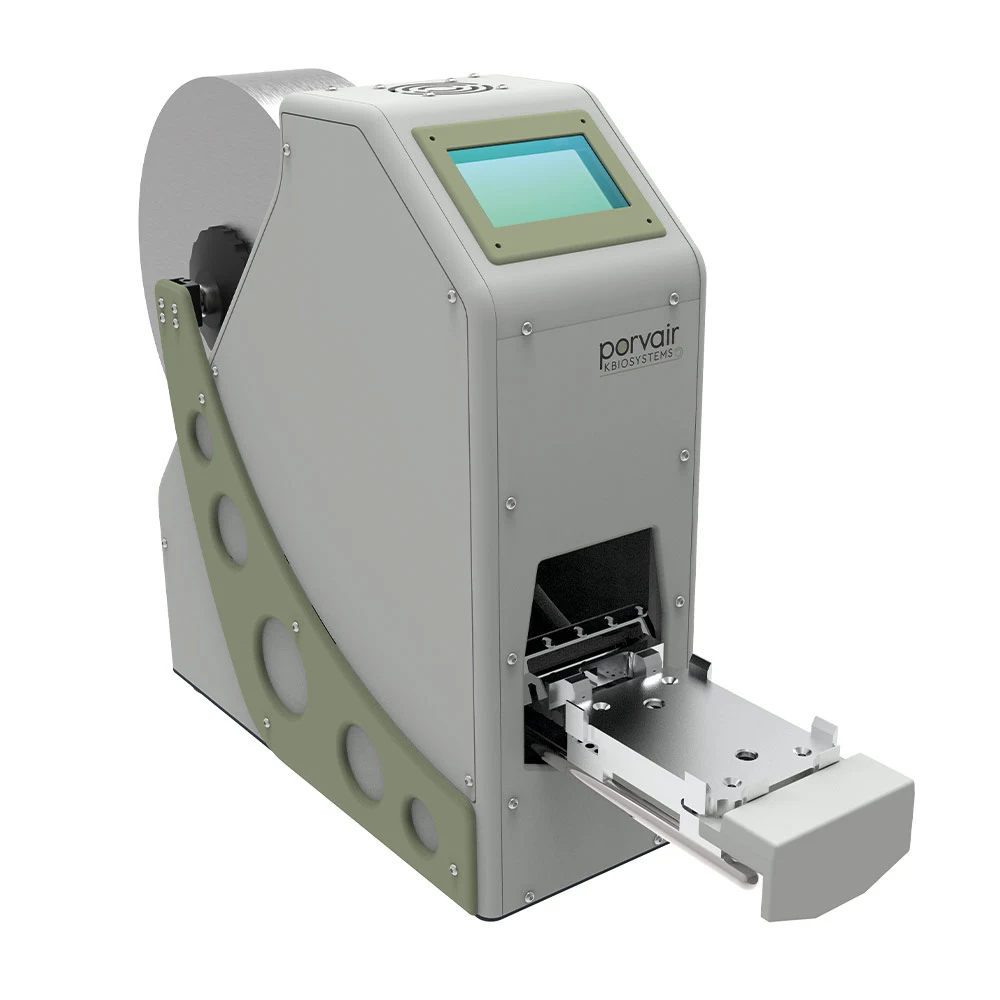

Ultraseal PRO and Ultraseal ePRO are automatic heat sealers that are fully compatible with laboratory automation. The difference between these two sealers is that the Ultraseal ePRO is purely electrically operated, while the Ultraseal PRO works pneumatically and requires a gas supply. The Ultraseal XT-PRO is based on the same principle as the Ultraseal PRO but can be used for plates with a height of up to 76 mm. Films or rolls are used for these sealers.

Ultraseal COLD-PRO is a sealer for adhesive sealing. In contrast to the heat sealers, no high temperatures are used for sealing.

Further information on consumables can be found on our Sealing Film & Foils page.

The Ultraseal LITE is a semi-automatic heat sealer that uses individual plates for sealing. The process is fully electric and requires no gas supply. This sealer is suitable for laboratories with a low to medium throughput.

The Ultraseal PRO works fully automatically and can be integrated into laboratory automation. By using rollers instead of individual plates, the throughput is significantly higher.

The Ultraseal ePRO works fully automatically and can be integrated into laboratory automation. By using rollers instead of individual plates, the throughput is significantly higher. Compared to the Ultraseal PRO, no gas supply is required.

Compared to the Ultraseal PRO, the Ultraseal XT-PRO is higher and therefore compatible with plates up to 76 mm high.

The Ultraseal COLD-PRO is used for adhesive sealing. Other films are used for this type of sealing.